Graded metal/insulator coating can create false constant-temperature infrared images

Researchers at the University of California, Berkeley have found a way to imbed visual “decoys” into surfaces of objects in a way that can fool IR cameras and systems into thinking that the decoy surfaces are at a different temperature than they are. In addition, even when the temperature of the object changes, the apparent temperature of the decoys doesn't.1

Junqiao Wu, UC Berkeley professor of materials science and engineering, and post-doctoral researcher Kechao Tang described a process in which they created special structures made from thin films of tungsten-doped vanadium dioxide in which the level of tungsten doping varied from front to back in the coating.

If desired, the coatings developed by the Berkeley researchers can effectively tune target objects into emitting the same infrared radiation as the surrounding environment, making them invisible to infrared detection devices.

In addition, the coatings can be manupulated in a way that a person trying to view the object with such a device would instead see a false image.

Vanadium dioxide is a substance that at certain temperatures can phase shift from an insulator, which suppresses electric conductivity, to a metal, which conducts electricity. With judicious engineering of the tungsten-doping profile, the insulator-metal phase transition can even out, allowing the substance to emit a constant level of thermal radiation over a wide range of temperature variations (T = 15 to 70 ºC). This state of equilibrium prevents a camera from detecting the true infrared signals that an object normally emits around room temperature.

Counteracting the blackbody temperature dependence

Specifically, the emissivity of the surface is designed to vary with temperature as the inverse of T4 (T to the fourth power), which exactly counteracts the T4 dependence of blackbody radiation.

Other researchers have explored concealing infrared emissions with different phase-changing materials. Previously, scientists at the University of Wisconsin at Madison experimented with samarium nickel oxide, while engineers at Zhejiang University (Hangzhou, China) focused on germanium-antimony-tellurium to achieve thermal camouflage.

But Berkeley researchers say their technology represents several advances. They grew layers of vanadium dioxide less than 100 nm thick on structures made from borosilicate glass and sapphire. Using pulsed lasers, researchers doped the films with different amounts of tungsten and then transferred the material onto a special adhesive tape called polyethylene (PE) film tape.

The researchers say this method provides better, more consistent camouflage because the product is mechanically flexible and inherently self-adaptive to temporal fluctuation as well as spatial variation of the target temperature. Additionally, by manipulating the configuration and composition of tungsten-doped vanadium dioxide on coatings applied to the PE tape, researchers can create an infrared decoy.

“How we grow the material changes the image people ultimately think they see,” Wu says.

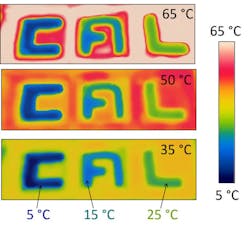

In the paper, researchers described encoding the letters C-A-L onto samples that they later placed on the surface of an object (see figure). The color of the letters represents the temperature people see when viewing from an infrared camera. For example, the blue C shows it is at a constant 5 ºC, the lighter blue A at a constant 15 ºC, and the green L at a constant 25 ºC, regardless of the actual temperature of the samples.

Even though the object’s actual temperature varies widely from 35 to 65 ºC, a person who views the object through night-vision goggles will distinctly see a colder “CAL” that is independent of the actual temperature.

“We can both erase real information and create false information,” Wu says, “CAL stays cool when the environment is hot.”

This kind of technology could prove useful for military and intelligence agencies, as they seek to thwart increasingly sophisticated surveillance technologies that pose a threat to national security. It might also incubate future encryption technology, allowing information to be safely concealed from unauthorized access.

Source: https://engineering.berkeley.edu/news/2020/07/surface-coating-can-create-false-infrared-images/

REFERENCE:

1. Kechao Tang et al., Advanced Materials (2020); https://doi.org/10.1002/adma.201907071.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.